In 1983, my mother bought a brand new Toyota Corolla for the princely sum of RM18,000. On a global scale, the price differentiation was between 5% and 10% either way. Five years later, said same Corolla was nearly RM60,000, this was double the price when based on the global average. How did this happen? Six letters from the English language that spelt doom for us as consumers and more frighteningly, for our automotive industry…P-R-O-T-O-N.

In the same way that a terminally ill patient learns to accept his or her fate, we in Malaysia have come to accept that it is our lot to pay outrageous prices for cars. The promises were legion, of course. A new industry, jobs, export and above all else, global recognition driven by some latent insecurity to “Show The World” – tallest flagpole, biggest roti canai, etc.

How the mighty have fallen. 30 years on, not only have we stagnated, we are now huffing and puffing to try and catch up with our neighbours who have slowly but surely built their automotive sectors into solid industrial platforms.

Thailand, more than any other country has benefited the most from our grandiose misadventures. Once a low-end assembler of pick-ups, today it is the undisputed Detroit of the East. In 2014, production registered 1.88 million vehicles, of which 1.12 million were exported, and this being a year where numbers took a hit due to a slump in local demand, but it still placed Thailand among the top 10 car exporters globally.

This did not happen by accident. When Malaysia started imposing big rent seeking measures and protectionist policies to benefit the few, it meant that growth was stunted. For global manufacturers, this was a big red flag because investment only follows growth. When the likes of Honda and Toyota saw their sales decimated due to unfair tariffs, they figured it was time to make some changes. Up till then, Malaysia was in prime position to be the motoring hub of Asia owing to a multitude of factors, least of which was that we were the largest passenger car market in South East Asia.

Malaysia’s loss was Thailand’s gain. They could smell the Tom Yam train and they jumped on it faster than you can say Sawadeekap. The country got rid of a lot of the regulation in the sector; unlike Malaysia, foreign firms do not need to enter joint ventures with local partners. Thailand’s Board of Investment offered incentives to produce eco-cars and the government cut the corporate tax rate from 30% to 20%, and this was in the last millennium!

What is more significant though is the ancillary effects of their policies. Thailand is no longer just a car assembly machine, it is a homegrown manufacturer of automotive parts. Cars produced here have the highest local content compared to other South-East Asia nations, according to market research firm, IHS. Thailand also exports parts worth billions, again more than all its ASEAN neighbours combined.

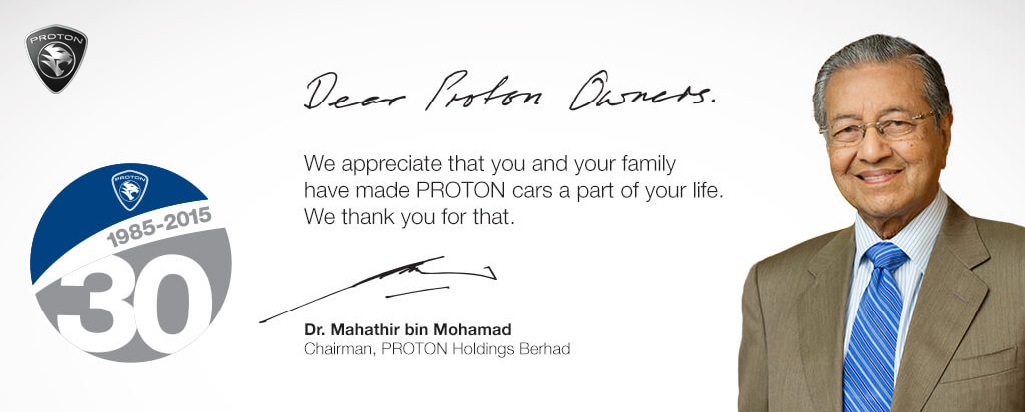

Many years ago, in a scintillating discussion on the automotive industry, a senior motoring journalist made a strange comment that I must admit, I failed to fully grasp at the time. After reading this article, I now understand what he meant. So while the good Doctor has been bestowed with many titles and accolades, here’s one that we often tend to forget – Father of the Thai Car Industry.