The news of Porsche setting up an assembly plant in Malaysia came as a bolt from the blue following a report by business weekly The Edge (also quoted in this Bloomberg story). While the report did not name source nor was it confirmed by its local partner, Sime Darby Motors, which happens to be the majority shareholder of the Inokom auto manufacturing facility in Kulim, Kedah – the rumoured site for the Porsche plant. Currently, BMW, MINI, Mazda and Hyundai assemble their CKD vehicles at Kulim.

The news of Porsche setting up an assembly plant in Malaysia came as a bolt from the blue following a report by business weekly The Edge (also quoted in this Bloomberg story). While the report did not name source nor was it confirmed by its local partner, Sime Darby Motors, which happens to be the majority shareholder of the Inokom auto manufacturing facility in Kulim, Kedah – the rumoured site for the Porsche plant. Currently, BMW, MINI, Mazda and Hyundai assemble their CKD vehicles at Kulim.

If the surprising news pans out, there are interesting times ahead not only on the business front as this could conceivably be Porsche’s first production facility outside of Germany, but also for the fans of the sports car brand who are licking their lips at the prospect of ‘more affordable’ Porsche vehicles, bearing in mind what’s ‘affordable’ is entirely subject to one’s personal wealth.

If the surprising news pans out, there are interesting times ahead not only on the business front as this could conceivably be Porsche’s first production facility outside of Germany, but also for the fans of the sports car brand who are licking their lips at the prospect of ‘more affordable’ Porsche vehicles, bearing in mind what’s ‘affordable’ is entirely subject to one’s personal wealth.

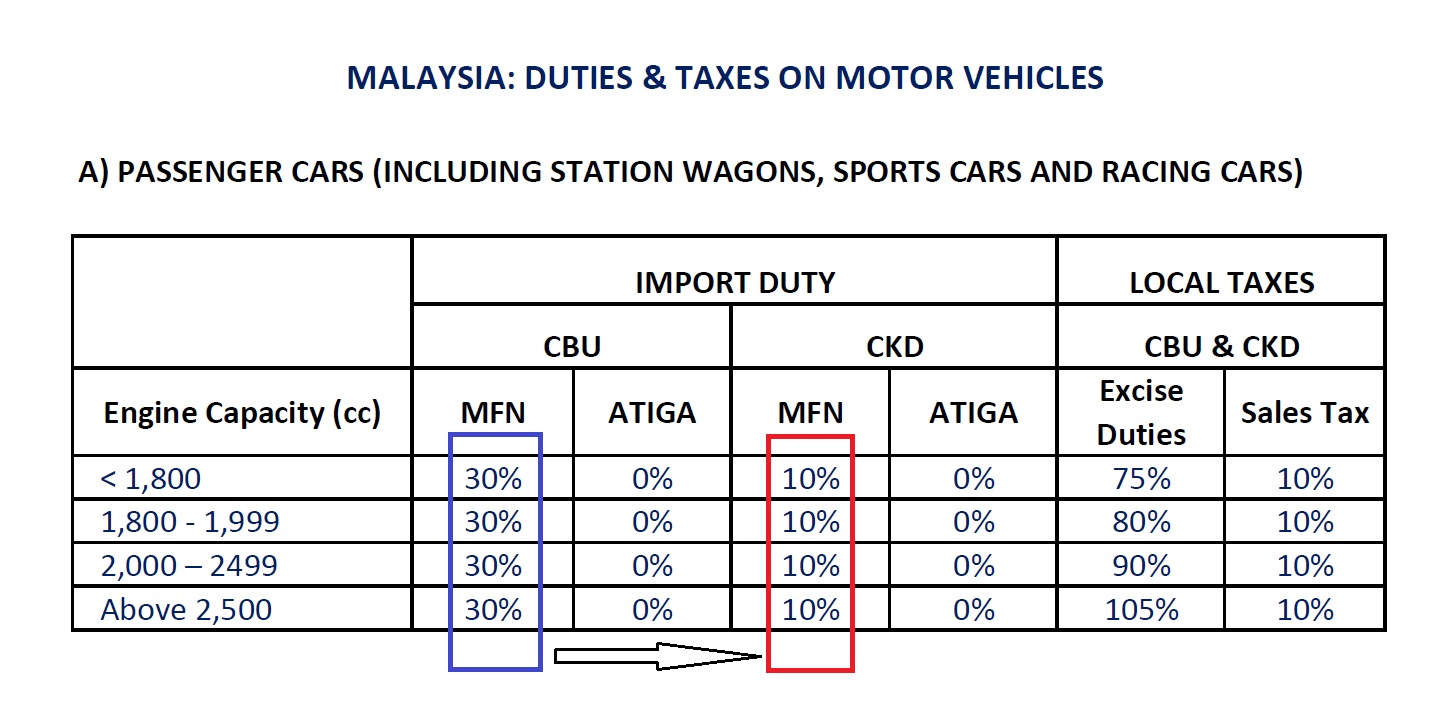

Based on Malaysia’s passenger vehicle duty structure and with the assumption of zero local parts used (at least from the beginning), there would be an immediate ‘savings’ of 20% in terms of import duties (from 30% to 10%) if a Porsche is to be assembled locally, with excise duties remaining as they are.

The savings on import duties would also have a compounded effect when excise and sales taxes are tabulated as the taxable base sum of the vehicle (after import duty applied) is smaller. So technically, locally assembled Porsches can be ‘cheaper’.

An example would be the Mercedes-AMG C43 which was priced at nearly RM500,000 in CBU form, it was later assembled locally and its retail price reduced by RM91,000. So yeah, Porsche models that are earmarked for local assembly can certainly become more affordable, but do note that retail prices are always subject to market forces, particularly for a luxury good such as a Porsche.

An example would be the Mercedes-AMG C43 which was priced at nearly RM500,000 in CBU form, it was later assembled locally and its retail price reduced by RM91,000. So yeah, Porsche models that are earmarked for local assembly can certainly become more affordable, but do note that retail prices are always subject to market forces, particularly for a luxury good such as a Porsche.

(Porsche delivered a total of 272,162 cars globally in 2020, which is just 3% below the sales record set in 2019 despite the impact of the Covid-19 pandemic.)